IoT 4.0

High Performance goes Cloud

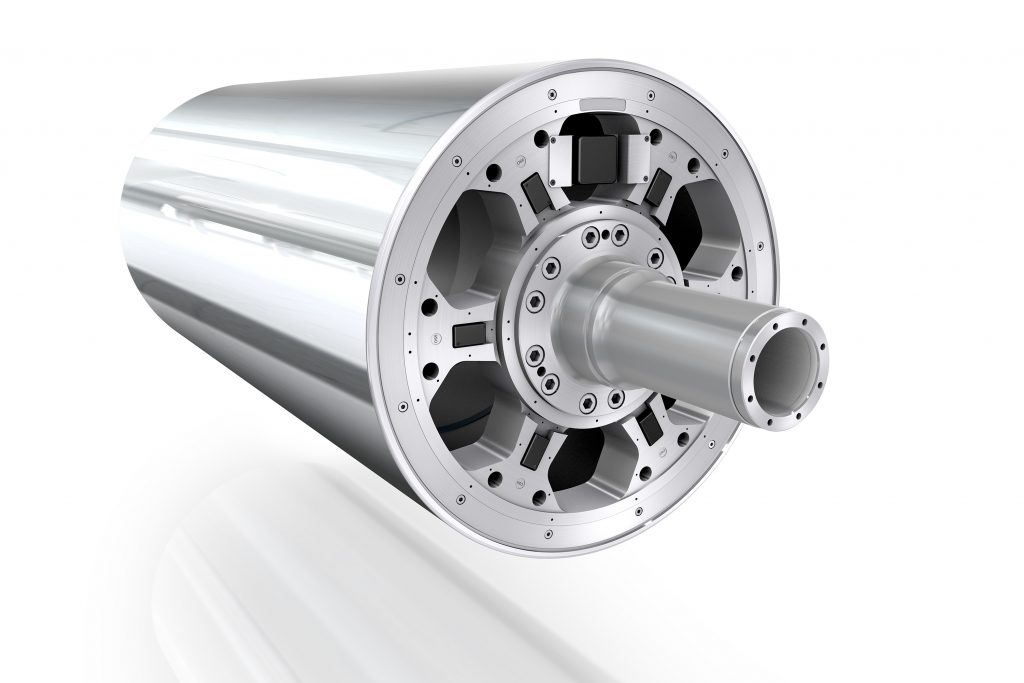

For our heating and cooling rollers, we have developed a cloud-based live monitoring system with which we can record and evaluate the performance values in real time and thus ensure the most long-term resource-saving and optimal use possible. A smart idea with a sustainable effect.

PROCESS CONTROL & OPTIMISATION

Live Data Monitoring

Knowledge of the real performance and operating data of cooling and heating rolls during the process is of decisive importance for optimum output with minimum energy input. In particular, the surface temperature of the roller in contact with the substrate is of utmost importance, because this is ultimately decisive for the desired cooling or heating processes. Only through precise monitoring and targeted control of the surface temperature can cooling or heating processes be optimally adjusted and plants operated with the greatest possible efficiency while simultaneously achieving maximum output.

And this is controlled and monitored over the entire service life of our heating and cooling rollers.

MEASUREMENT DATA

ultra-high-precision

The core of our measuring method is our own developed, ultra-high resolution temperature measuring sensors, with which it is possible to directly determine the surface temperature of the roller. By combining this with high-resolution pressure sensors, the performance of the roller can also be monitored over a longer period of time and any necessary maintenance work can be commissioned and scheduled in good time. The best prerequisites for optimum system operation and minimum downtimes.

MONITORING

Cloud-Computing as a service

The measurement data determined at the roller are transmitted via an encrypted internet connection to the cloud-based storage and computing unit, where they are prepared and further processed. The values calculated in this way, the performance data of the roller, the surface temperatures and pressures are made available to the system operators via a web frontend, independent of the platform. The roller is thus monitored in real time via secure, encrypted cloud access with a platform-independent software solution from any device and from any location.

If desired, the data can also be forwarded directly to the respective plant control system via a corresponding interface.

IT-BACKBONE & SECURITY

CAM-Technology

By using Azure IoT Hub as a backbone, nothing stands in the way of a worldwide deployment of our solution. The scaling and security of our solution is thus guaranteed globally. Migration to an existing customer’s own Azure IoT environment with complete control over their own data is also possible at the touch of a button.

Integrate your own devices and solutions into the Azure IoT Hub to have a comprehensive overview and complete integration of your applications on a secure and globally available platform.

WOULD YOU LIKE TO FIND OUT MORE?

Then get in touch with us. Find out more about our business units. We would be happy to arrange a non-binding appointment. Just give us a call or write us an e-mail.