BUSINESS UNIT COMPOSITES

Cylite® – Driven by Performance

Our long term experience with the production of composite components with a wide variety of test- and detail improvements are the basis for the state-of-the-art process technology to manufacture various components using a different production processes. Within our industry we have set a new benchmark with our high performance filament winding procedure Cylite®.

APPLICATIONS

Amazing Diversity

The manufacturing of rolls made of CFRP is still one of our core products within our product portfolio. Especially, where high speed at slim dimensions or special demands on balance and damping characteristics, low weights and rotation moments or minimum bending is required, rolls made of CFRP are preferably used. Today, particularly customers who belong to the foil producing industry and to paper processing-, print- as well as non-woven industry are our regular customers.

Numerous industrial applications such as drive shaft elements for steady- as well as mobile lines in the wind energy or in the exploration sector belong also to our product portfolio as well as e. g. supporting- respectively beam elements for infrastructure- or mobile crane units.

INDUSTRIES

Unlimited Applications

In the meantime, the application of Carbon Fibre Reinforced Plastics (CFRP) respectively glass fibre (GFK) is normal practice in many industries. Due to the outstanding specific characteristics and individual adjustment of the component characteristics on the individually demanded application, it is generally possible to develop optimal products featuring the best possible coordinated characteristic profile.

Meanwhile, our products can be found in many different applications and industries. As engineering- and manufacturing partner we deliver to the Engineering industry, wind energy, marine sector, electro industry as well as infrastructure industries and civil engineering.

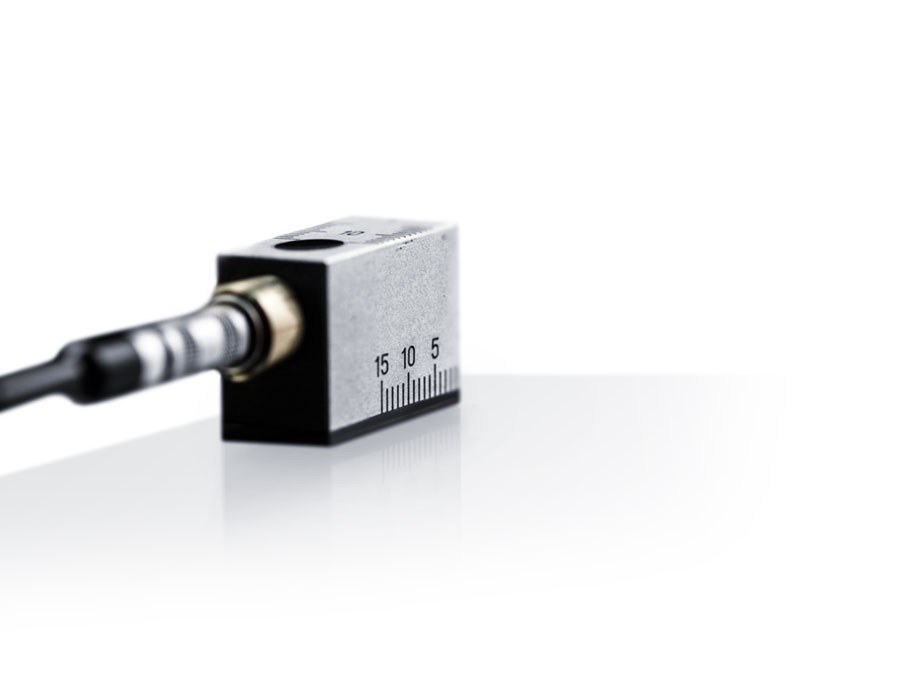

DIMENSIONS AND TOLERANCES

(Nearly) Unlimited Dimensions

With our variety of manufacturing processes, we can meet the requirements and desires of our customers for a very large range of dimensions. When using thermosetting resin systems, we are currently able to manufacture parts up to 15 m in length and 1.5 m in diameter. For nonrotation-symmetrical components, the dimensional limits result from the individual component geometry as well as the resin system used. However, all our products have the highest component quality with minimal manufacturing tolerances.

MATERIALS

with Taylor-Made Properties

The use of composite materials makes it possible to provide the optimum individual adaptation of the mechanical and thermal component properties to the corresponding application. We exclusively manufacture products made of carbon (CFRP) and glass fiber composite materials (GRP) using high-quality fibers with minimal material tolerances and corresponding resin systems. Since we offer an extremely broad range of products, we rely exclusively on long-term partners with reliable manufacturing processes and known materials properties. These are prerequisites for an efficient and unbeatable engineering and manufacturing process.