ROLLS

Design Principles

Since there are many different applications for rolls, we have many different answers for the requirements. We therefore classify our designs according to their design principles in order to be able to maintain an overview of the large number of individual solutions.

We would like to show you the most important of these below.

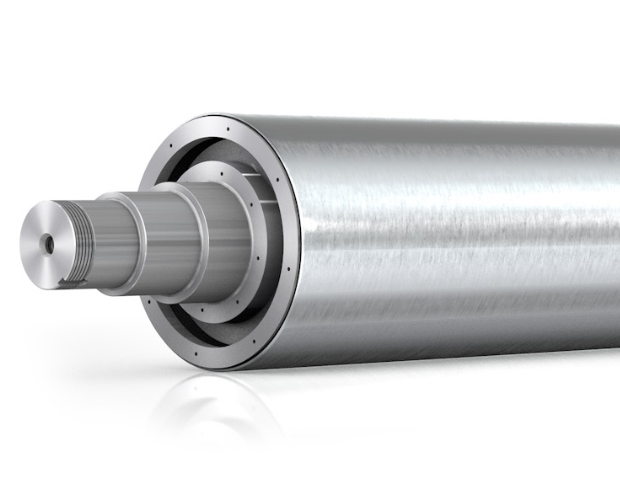

SINGLE SHELL

A sleek solution

Single shell rolls are probably the simplest category of roll designs. Thanks to their minimal weight and high cost-effectiveness, they are a suitable and adequate solution for many applications. They can be optionally upgraded using simple spraying fittings for both steam-heated or straightforward heating or cooling applications. Due to the use of a wide variety of materials, including composite materials, the diversity of applications is almost unlimited. In combination with flanged pins, maintenance work on the bearing points can also be carried out within the systems themselves.

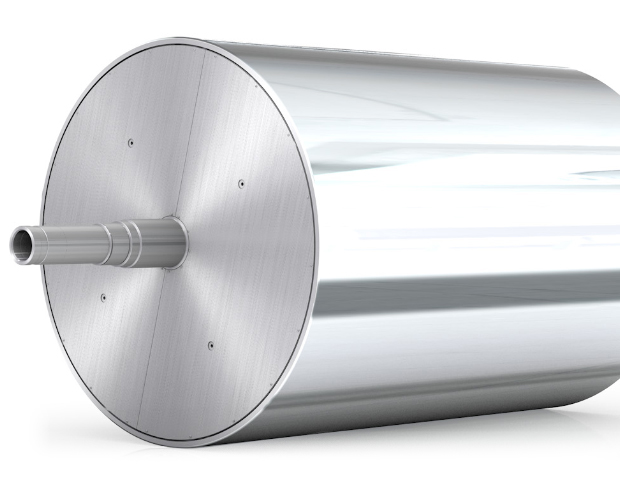

DOUBLE SHELL

Thermal Precision next generation - IoT 4.0

For demanding thermal requirements with high-level requirements in terms of heating and/or cooling performance, precise temperature profiles, low pressure losses and high speeds, rolls with a double shell design are used almost exclusively. The individual design of the media guidance depends on the conditions in the system as well as the special wishes of our customers. Due to the use of standardized principles and modules, we always try to satisfy individual requirements with a great deal of precision and efficiency.

With our cloud-based IoT4.0 solution, we offer the possibility to monitor the performance data of our products in real time and to specifically influence the production parameters. For us, this is the basic prerequisite for energy-saving production with maximum output.

We are therefore sure to find the right solution for you.

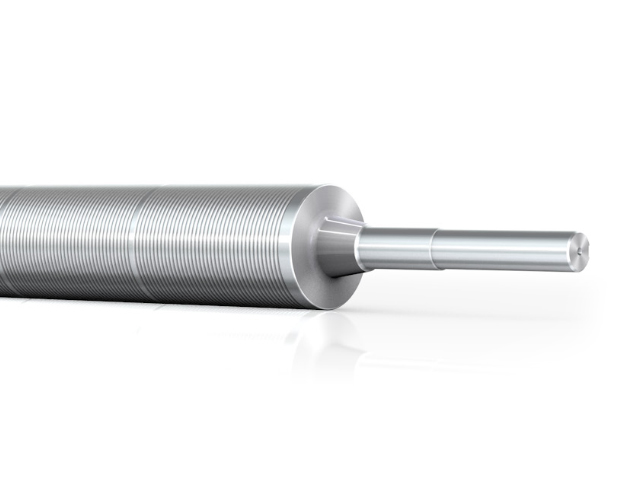

SOLID SHAFTS

Massively Machined

Solid shafts represent a special case of rotating products. We are happy to face any conceivable challenge in the areas of turbines and fans, transmissions, axles, shafts and rolls. In this way, we are able to produce almost any surface contour by turning, milling, grinding, drilling, or hardfacing, as well as with additional surface coatings, if required. Especially adapted to your particular requirements.

WINDING MANDRELS

Reliable Core

For the precise production of glass (GRP) or carbon fiber-reinforced (CFRP) tube constructions using the winding process, we manufacture highly precise winding mandrels according to your specifications. The winding mandrels are designed as single-shell or double-shell constructions and thus represent a special case of typical roll constructions. Low bending deflection, the best possible balancing and mold tolerances, as well as high-quality surfaces guarantee stable serial production of GRP or CFRP semifinished products for a wide variety of end-use applications.

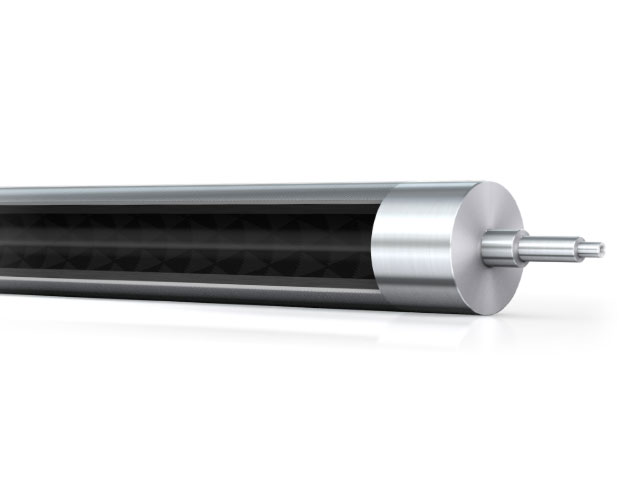

HYBRIDCORE©

Composite Core – Metal Surface

The revolutionary latest generation of our HybridCore® rolls is characterized by the combination of a Cylite® CFRP core with a metal surface. This results in outstanding performance product characteristics for the user without changing the look and feel. A significantly reduced weight of up to 70% as well as a reduced mass moment of inertia of up to 65% enable significantly more efficient bearing, drive and brake concepts, which are decisive in ensuring that the latest generation of systems runs optimally and smoothly.

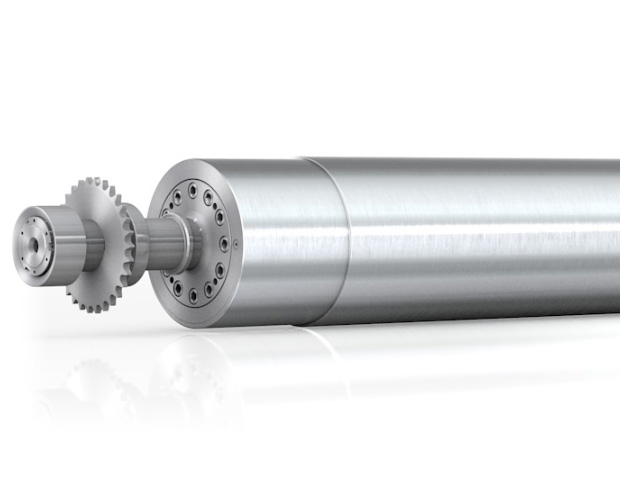

SPECIAL DESIGNS

Specialized Answers

We assign special customer requirements that can not be assigned to the typical design principles to the “Special designs” section. The development of special solutions has been part of our service portfolio for many years. We manufacture both rolls with complex surface geometries for cutting processes (cutter spindles) or for the production of carbon fibers as well as special designs with highly favorable specific, static and dynamic characteristics. These include, for instance, low-deflection contact or smoothing rolls as well as suction/vacuum rolls for the plastics industry. Therefore, we are certain that we can also find the right solution for your problem.